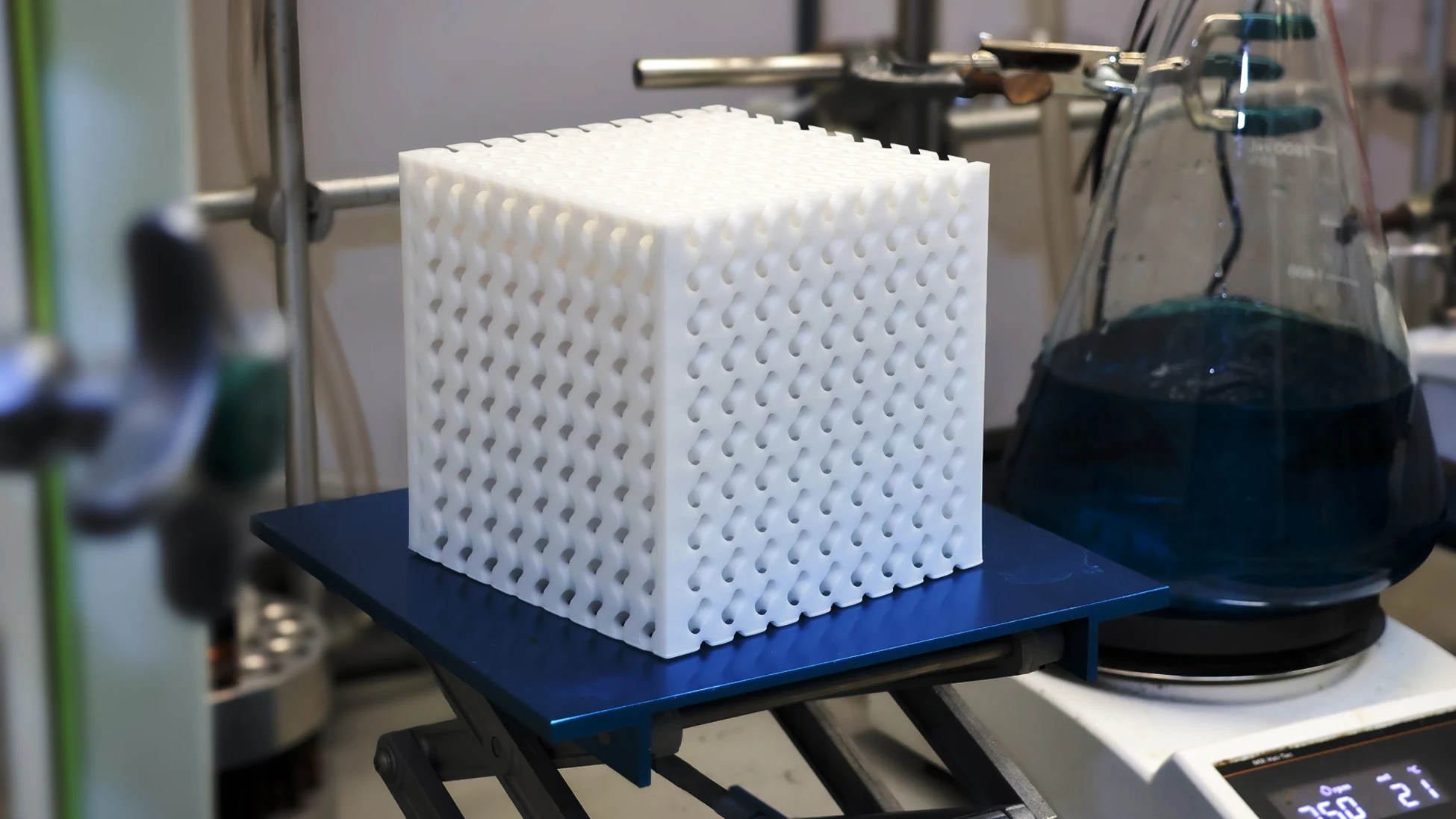

"At a mine or industrial site, tailings or wastewater can flow through a series of the cartridges, each targeting a specific element. The receptors bind minerals in alcohol and release them when they're rinsed with water, using little energy and avoiding the use of toxic chemicals. The process, which the company says is 100 times more selective and faster than current rare earth refining, can also be used on electronic waste."

"Supra, a startup that spun out of the University of Texas at Austin, is taking a different approach that's clean, low-cost, and makes it possible to capture some of the billions of dollars' worth of critical minerals that are trapped in waste in the U.S. The company's technology uses supramolecular receptors, "a string of molecules built to grab specific molecules like a baseball glove," says CEO Katie Durham."

Rare earth elements are abundant but difficult to refine into the purified forms needed for electronics and clean-energy technologies. Standard refining processes are toxic and have concentrated production in China. Supra developed supramolecular receptors—molecular strings engineered to bind specific metal ions—embedded in a porous polymer and 3D-printed into reusable cartridges. Tailings or wastewater flow through cartridges that target individual elements; receptors bind minerals in alcohol and release them when rinsed with water, minimizing energy use and avoiding toxic chemicals. Lab tests captured 100% of cobalt and fully isolated it from lithium, and the process can be applied to electronic waste.

Read at Fast Company

Unable to calculate read time

Collection

[

|

...

]