"Making the dry electrode process work at scale, which is a major breakthrough in lithium battery production technology, was incredibly difficult. Congratulations to the @Tesla engineering, production and supply chain teams and our strategic partner suppliers for this excellent achievement!"

"cuts cost, energy use & factory complexity while dramatically increasing scalability."

"Getting dry electrode technology to scale is just the beginning."

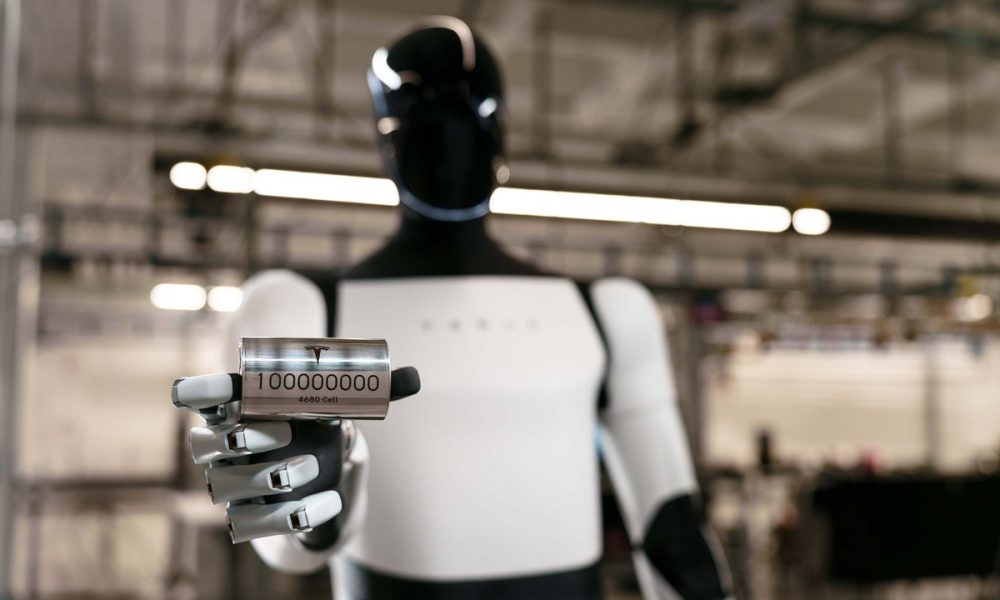

Tesla is producing 4680 battery cells with both anode and cathode manufactured using a dry-electrode process at its Austin facility. Scaling the dry-electrode process was described as incredibly difficult and required significant engineering, production, supply-chain coordination and partner supplier effort. Dry-electrode manufacturing cuts cost, energy use and factory complexity while dramatically increasing scalability. The dry-electrode concept was introduced in 2020 to eliminate solvent-based electrode drying, shrink factory footprints, and lower capital expenditures. Industrializing the dry cathode proved more challenging than expected. Production of Model Y vehicles with 4680 battery packs has begun.

Read at TESLARATI

Unable to calculate read time

Collection

[

|

...

]